Imishini Yokugcwalisa I-Vial Ekhemisi

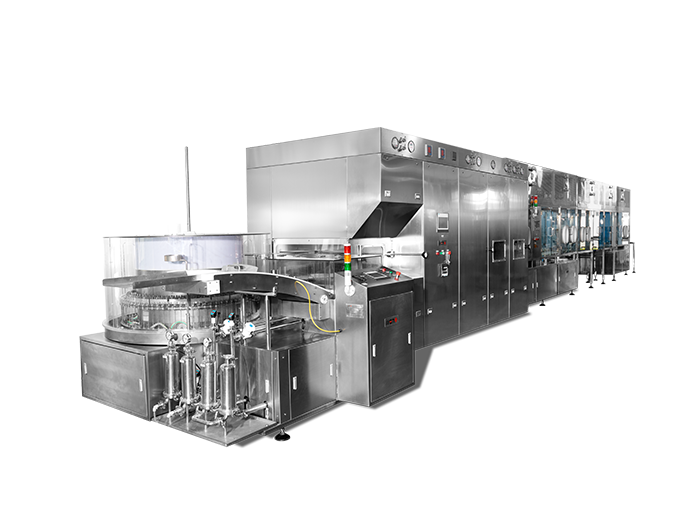

Iimishini yokugcwalisa i-vialisetshenziswa kakhulu embonini yezemithi ukugcwalisa izitsha ngezithako zokwelapha. Le mishini ehlala isikhathi eside iklanyelwe ukwenza umsebenzi onembile wokugcwalisa i-vial ngokushesha. Imishini yokugcwalisa i-Vial iqukethe namakhanda amaningi okugcwalisa abasiza ukuba bafinyelele izinga eliphezulu lokugcwalisa kanye nokukhiqiza okukhulayo ukuze bahlangabezane nezidingo zemboni yezemithi. Kunezinhlobonhlobo eziningi zemishini yokugcwalisa i-vial efanelekile izinhlelo zokusebenza ezahlukene embonini yezemithi.

Umshini Wokugcwalisa Ibhodlela Umgomo Wokusebenza

Iumshini wokugcwalisa i-vialiqukethe i-SS slat conveyor yokuhamba kalula kwezitsha emshinini wokugcwalisa. Kusuka ebhandeni lokuthutha, izitsha ezingenalutho ezinenzalo zibe sezidluliselwa esiteshini sokugcwalisa, lapho izithako zemithi ezidingekayo zigcwaliswa ngobuningi obunembile. Iziteshi zokugcwalisa ziqukethe amakhanda amaningi noma imibhobho evumela ukugcwaliswa kwe-vial ngokushesha ngaphandle kokumosha. Inani lamakhanda okugcwalisa ukusuka ku-2 kuye kwangama-20 lingenziwa ngokwezifiso ngokwemfuneko yokukhiqiza. Izitsha zigcwaliswa kahle ngamakhanda okugcwalisa, emva kwalokho izitsha ezigcwele zidluliselwa esiteshini esilandelayo emugqeni wokugcwalisa. Umshini ugcina ubunyumba obungaguquki kuyo yonke imisebenzi yokugcwalisa. Esiteshini esilandelayo, izivalo zibekwe phezu kwekhanda lezitsha. Lokhu kuqinisekisa ukuthi ubunyumba nobuqotho bezingxenye s buyagcinwa. Ngesikhathi sokugcwalisa, kubalulekile ukuqinisekisa ukuthi izithako zemithi nezitsha azinawo ukungcola. Noma yikuphi ukuphazamiseka ngokwakheka kwamakhemikhali ezingxenyeni kungabeka engcupheni yonke inqwaba yezitsha ezigcwalisiwe futhi kungase kuphumele ngisho nasekunqatshweni kwayo yonke inqwaba. Izitobha zibe sezimbozwa futhi zivalwe ngaphambi kokuya esiteshini sokulebula.

Izinhlobo Zemishini Yokugcwalisa Ibhodlela

Kuwukuhlakanipha ukuqonda izinhlobo ezahlukene zemishini yokugcwalisa i-vial etholakalayo kanye nomklamo wayo, isicelo kanye nenqubo yokusebenza. Ngezansi sichaza izinhlobo ezahlukene zemishini yokugcwalisa i-vial ngolwazi lwayo:

Umshini Wokugcwalisa Ibhodlela

Iumshini wokugcwalisa i-vial wemithiesetshenziswa embonini yemithi ibizwa nangokuthi umshini wokugcwalisa i-vial umjovo futhi ihlanganisa i-vial filler kanye nezivalo zenjoloba. Le mishini yokugcwalisa i-vial ezenzakalelayo iqinisekisa ukuvumelana kwevolumu, inciphisa ukulahleka komkhiqizo, futhi iza nesistimu yokulawula ikhwalithi eyakhelwe ngaphakathi yokuhlola ivolumu yesikhathi sangempela se-vials. Imishini yokugcwalisa i-vial yemithi isetshenziswa kuzo zombili izinhlelo zokusebenza eziyinyumba nezingezona oyinyumba.

Umshini Wokugcwalisa I-Vial Liquid

Iumshini wokugcwalisa uketshezi lwe-vialiqukethe umshini oyinhloko, i-unscrambler, i-conveyor, isitsha sokuphakela isitobha kanye ne-scrambler. Ibhande lokuthutha lidlulisela izitsha ziye esiteshini sokugcwalisa, lapho okuqukethwe koketshezi kugcwaliswa emshinini. Imishini yokugcwalisa uketshezi lwe-vial igcwalisa uketshezi noma uketshezi lwama-viscosity ahlukahlukene ezitsheni. Le mishini isetshenziswa kabanzi embonini yezemithi ukuze kuqinisekiswe ukugcwaliswa okunembile kwezitsha. Umshini wokugcwalisa uketshezi lwe-vials usebenza ku-diving nozzle kanye nesimiso se-volumetric, esihlinzeka ngokusebenza kokugcwalisa okuyinyumba nokunemba.

Umshini Wokugcwalisa I-Vial Powder

Iumshini wokugcwalisa i-vial powderkuhlanganisa ukugeza, ukuvala inzalo, ukugcwalisa, ukuvala nokulebula. Yonke imishini iqondaniswe emugqeni wokugcwalisa ukuze kuqinisekiswe ukukhiqizwa okuqhubekayo kwamabhodlela embonini yezemithi. Umshini ozenzakalelayo wokugcwalisa i-vial powder ubalulekile embonini yezemithi ngoba lokho kusiza ukugcwalisa ama-granules noma impushana ezitsheni.

Umshini Wokugcwalisa Uketshezi Umjovo

Umugqa wokugcwalisa uketshezi noma umshini usebenza ngaphansi kwengcindezi ephezulu. Ngakho-ke, kungase futhi kuhlukaniswe njengokugcwalisa ingcindezi ye-liquid. Kule nqubo, umjovo owuketshezi ugeleza ebhodleleni lokugcina kuye ngesisindo lapho ukucindezela ku-reservoir yamanzi kufana nokucindezela komoya ebhodleleni.

Iimigqa yokugcwalisa uketshezi lomjovokulula ukusebenza futhi ugcwalise inani eliqondile loketshezi emabhodleleni, ezitsheni noma kumagalani. Indlela yokugcwalisa eyakhelwe emshinini ikuvumela ukuthi ulungise izinga lokugcwalisa kanye nenani ngosayizi webhodlela noma isitsha ngaphandle kokufaka noma yiziphi izingxenye. Le mishini ifakwe izinzwa ezikwazi ukumisa inqubo ngokuzenzakalelayo ngaphandle kwebhodlela ebhandeni.

Isikhathi sokuthumela: Nov-20-2024