Imishini yokugcwalisa i-ampouleziyimishini ebalulekile embonini yezemithi neyokunakekelwa kwezempilo ukuze kugcwaliswe ngokunembe nangempumelelo kanye nokuvala ama-ampoules. Le mishini yakhelwe ukuphatha isimo esintekenteke sama-ampoules futhi iqinisekise ukugcwaliswa okunembile kwemithi noma izixazululo eziwuketshezi. Ukuqonda imigomo engemuva kwemishini yokugcwalisa i-ampoule kubalulekile ukuze uqonde ukusebenza nokubaluleka kwayo ekwenziweni kwemithi.

Imigqa Yokugcwalisa I-Ampouleziwuhlobo lwemishini yokwenza imithi esetshenziselwa ukugcwalisa nokuvala ama-ampules. Lawa madivayisi ahlangene futhi agcina ukuvumelana ngesikhathi sokugcwalisa nokufaka uphawu. Umshini Wokugcwalisa I-Ampoule Nomshini Wokufaka uphawu noma umshini wokugcwalisa i-ampoule wenza uphawu lokugcwalisa olwakhelwe kubuchwepheshe obuthuthukisiwe ukuze kufezwe isidingo embonini yokugcwalisa i-Pharmaceutical. Ama-ampoule afakwa ngoketshezi abese ehlanzwa ngegesi ye-nitrogen futhi agcine evalwa kusetshenziswa amagesi avuthayo. Umshini unepompo yokugcwalisa eklanywe ngokukhethekile ukuze kugcwaliswe uketshezi olunembile ngokugxilisa intamo ngesikhathi sokugcwalisa. Ama-ampoule avalwa ngokushesha ngemuva kokugcwalisa uketshezi ukuze kugwenywe ukungcola. Aphephile futhi ukuthi asetshenziswe ekugcinweni nasekuthuthweni kwemithi ewuketshezi neyimpushana.

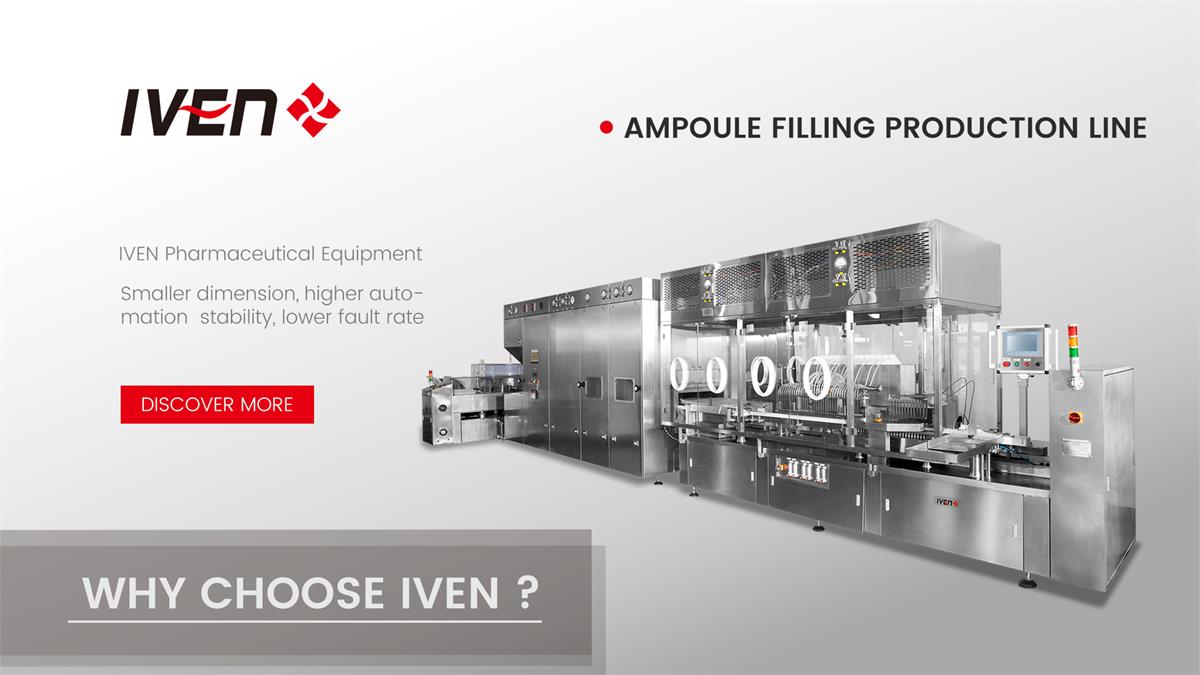

IUmugqa wokukhiqiza wokugcwalisa i-Ampoule ihlanganisa umshini wokuwasha we-ultrasonic oqondile, umshini wokomisa inzalo we-RSM kanye nomshini wokugcwalisa we-AGF nomshini wokuvala. Ihlukaniswe yaba indawo yokuwasha, indawo yokuvala inzalo, indawo yokugcwalisa kanye nendawo yokubeka uphawu. Lo mugqa ohlangene ungasebenza ndawonye futhi ngokuzimela. Uma kuqhathaniswa nabanye abakhiqizi, okokusebenza kwe-VENN'S kunezici ezihlukile, okuhlanganisa ubukhulu obuphelele obuncane, i-automation ephakeme & ukuzinza, isilinganiso esiphansi samaphutha nezindleko zokuyilungisa, njll.

Umgomo womshini wokugcwalisa i-ampoule ukukala ngokunembile uketshezi futhi ugcwalise kuma-ampoules ngamanye. Umshini usebenza nge-volumetric noma indlela yokugcwalisa isirinji, uqinisekisa ukuthi inani eliqondile lomkhiqizo likhishwa ku-ampoule ngayinye. Lokhu kufezwa ngochungechunge lwezinqubo ezilinganiswe ngokucophelela ezihlanganisa ukukala okunembayo nokudluliswa komuthi owuketshezi.

Ukusebenza komshini wokugcwalisa i-ampoule kusekelwe ezingxenyeni eziningana ezibalulekile nezinqubo. Okokuqala, ama-ampoules alayishwa ohlelweni lokuphakela umshini bese ethuthwa esiteshini sokugcwalisa. Esiteshini sokugcwalisa, kusetshenziswe indlela yokugcwalisa efana ne-piston noma iphampu ye-peristaltic ukuze kukhishwe umthamo oqondile woketshezi ku-ampoule ngayinye. Ama-ampoule agcwalisiwe abe esehanjiswa esiteshini sokuvala lapho evalwa khona ukuze kuqinisekiswe ubuqotho bomkhiqizo.

Enye yezimiso eziyisisekelo zemishini yokugcwalisa i-ampoule isidingo sendawo eyinyumba nengenakho ukungcola. Imishini ifakwe izici eziphambili ezifana nokugeleza komoya kwe-laminar, uhlelo lokuvala inzalo nokusebenza kwe-Clean in Place (CIP) ukuze kugcinwe izinga eliphezulu lokuhlanzeka nokuphepha komkhiqizo. Lokhu kubalulekile ekwenziweni kwemithi, lapho ukugcinwa kokuhlanzeka komkhiqizo kanye nokuba msulwa kubalulekile.

Esinye isimiso esilawula ukusebenza kwemishini yokugcwalisa i-ampoule isidingo sokunemba nokunemba. Imithi yoketshezi kufanele ifakwe umthamo futhi igcwaliswe ngokunemba okukhulu ukuze kuqinisekiswe ukuthi i-ampoule ngayinye iqukethe umthamo ofanele. Lokhu kufinyelelwa ngokusetshenziswa kwezinhlelo zokulawula eziphambili nezinzwa eziqapha futhi zilawule inqubo yokugcwalisa ukuze kuncishiswe ukuhlukahluka nokuqinisekisa ukuvumelana.

Ngaphezu kwalokho, umgomo wokuguquguquka uyingxenye ebalulekile yemishini yokugcwalisa i-ampoule. Le mishini iklanyelwe ukuhlalisa izinhlobonhlobo zamasayizi nezinhlobo ze-ampoule, okuvumela ukuguquguquka ekukhiqizeni. Kungakhathaliseki ukuthi ama-ampoules ajwayelekile, ama-vials noma ama-cartridges, umshini ungashintshwa ukuze uphathe amafomethi ahlukene, uwenze ulungele ukusetshenziswa kwemithi ehlukahlukene.

Kafushane, izimiso zokunemba, ubunyumba kanye nokuguquguquka zisekela ukusebenza kwemishini yokugcwalisa i-ampoule. Le mishini idlala indima ebalulekile ekwenziweni kwemithi, iqinisekisa ukudotshwa okunembile kanye nokugcwaliswa kwemithi ewuketshezi kuma-ampoule ngenkathi igcina izindinganiso eziphakeme zokuhlanzeka nobuqotho bomkhiqizo. Ukuqonda imigomo engemuva kwemishini yokugcwalisa i-ampoule kubalulekile ukuze uqonde ukubaluleka kwayo ekukhiqizweni kwemithi kanye nemboni yezokunakekelwa kwempilo iyonke.

Isikhathi sokuthumela: Aug-16-2024