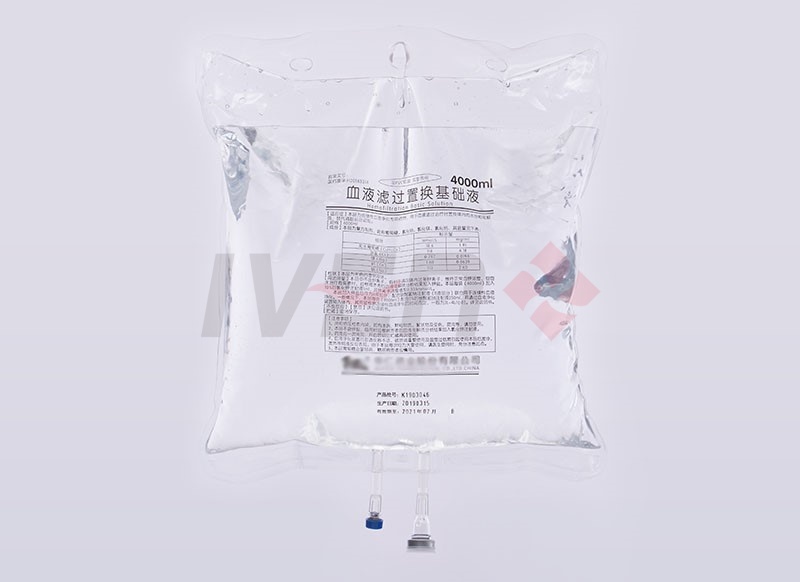

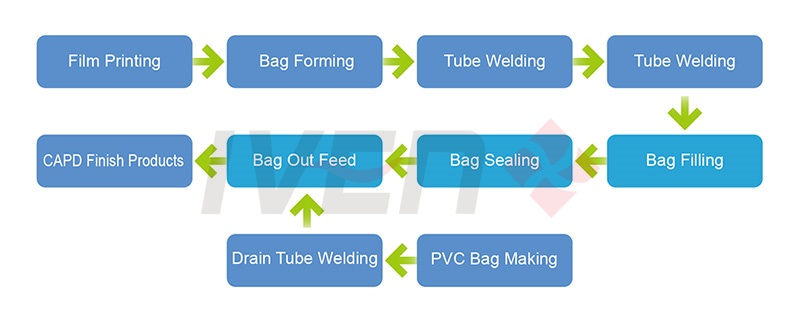

I-Peritoneal Dialysis Solution (CAPD) Production Line

EyethuUmugqa wokukhiqiza we-Peritoneal Dialysis Solution, Ngesakhiwo Esihlangene, esithatha indawo encane. Futhi idatha ehlukahlukene ingalungiswa futhi ilondolozelwe ukushisela, ukuphrinta, ukugcwalisa, i-CIP ne-SIP njengezinga lokushisa, isikhathi, ingcindezi, nayo ingaphrintwa njengoba kudingeka. Idrayivu eyinhloko ehlanganiswe ne-servo motor enebhande le-synchronous, isikhundla esinembile. Imitha yokugeleza kwenqwaba ethuthukisiwe inikeza ukugcwaliswa okunembayo, ivolumu ingalungiswa kalula ngesibonisi somshini womuntu.

Okokuphrinta kwesikhwama sesixazululo se-CAPD, ukwakha, ukugcwalisa nokufaka uphawu, i-tube welding, umshini wokwenza isikhwama se-PVC.

I-Peripheral welding enesakhiwo sesikhunta esivulekile esiphindwe kabili kanye nesikhunta esishintshashintshayo ifakwe ipuleti lokupholisa, yenza isikhunta esishintshashintshayo sibe nezinga lokushisa elifanayo, futhi siqinisekise ukuthi okokusebenza ekubumbeni nasekumiseni ngeke kubhake ulwelwesi olushisayo; Kuthuthukiswe ikhwalithi yomkhiqizo.

Ipayipi elishisisayo kanye ne-thermocouple kupuleti lokushisisa ingxubevange ye-aluminium, ukushisisa nokudluliswa kokushisa kuyafana, ukulawulwa kwezinga lokushisa kunemba, kunciphise ukulahlekelwa ukushisa, ngeke kubonakale izinga lokushisa langempela kanye nezinga lokushisa lokubonisa lingahambisani, ukuze kuqinisekiswe izinga lokufaneleka lokushisela.

Ukusetshenziswa kwefilimu okungu-100%, akukho udoti ophakathi kwezikhwama namaqembu.

Isikhunta esakhayo siklanywe ngokukhethekile. Isikhwama sokugcina esakhiwe seqembu langaphambili sizosikwa kanye nesikhwama sokuqala esakhiwe seqembu lakamuva. Kuhle ukuhudulwa kwefilimu lapho welula izikhwama. Uhlelo olulodwa kuphela olungaqinisekisa ukwelula kwefilimu nokwelula kwesikhwama kungenziwa ngokuhambisana. (iqinisekisa ubude befilimu obushubile obufanayo besikhathi ngasinye phakathi kweqembu ngalinye, okungukuthi akukho umkhawulo wokulahla phakathi kwamaqembu ahlukene - umakhi wasekhaya ukhona udoti phakathi kweqembu ngalinye.)

Lapho ushintsha isikhunta ngemininingwane ehlukene yemikhiqizo, udinga kuphela ukuguqula isikhunta esingaphezulu, isikhunta esingezansi singashintshwa isikhunta esijwayelekile, esingasindisa kakhulu isikhathi sokulungisa iphutha. Ukwakha isikhunta kwenziwa ngezinto ezikhethekile kanye nenqubo ekhethekile yabakhiqizi abakhethekile besikhunta, okuqinisekisiwe ukuthi akumaki ngekhwalithi kanye nempilo yesevisi yezikhwama eziyizigidi eziyi-100.

Njengokwezimpawu zepulasitiki yokushisela, ukushisela okubandayo kufanele kwamukelwe ngokushesha ukuze kwakhiwe ngemuva kokushisela okubili kokushisa okuphezulu. Lokhu kungaqinisekisa kokubili ukuqina kwe-welding yepulasitiki futhi ilethe ukubukeka okuhle. Ngakho-ke, izimbobo zokushisela zesibili zidinga ukushisela okubandayo, nezinga lokushisa lokushisela lamanzi okupholisa langempela (15ºC-25ºC), isikhathi nokucindezela kuyalungiseka.

Ngomklamo welungelo lobunikazi, isiteshi sokususa udoti silula futhi sithembekile, izinga lokuphasa eliphezulu lifika ku-99% nangaphezulu. Izinti ezingenhla nezingaphansi zibopha ifilimu yemfucuza ngemuva kokwakheka kwesikhwama futhi ziyidabule ngesilinda esiqondisayo, ukuze kuqedelwe ukwenza isikhwama. Unqenqema lwemfucuza engunxantathu luqoqwa ngomshini okhethekile. Isiteshi sokususa imfucuza esizenzakalelayo asikwazi nje ukunciphisa imiphumela emibi yokudabula okwenziwa, kodwa futhi siqinisekise ukuma kwesikhwama esihle.

Yamukela isilinganiso se-E + H mass flowmeter kanye nesistimu yokugcwalisa ingcindezi ephezulu.

Iphampu yokulawula imvamisa ilawula ukucindezela, sebenzisa ipayipi le-silicone lezokwelapha elimelana nokucindezela okuphezulu ukuxhuma ipayipi, ukunakekelwa okulula, akukho ndawo efile yokuhlanza.

Ukunemba kokugcwalisa okuphezulu, akukho sikhwama futhi akukho sikhwama esifanelekayo, akukho ukugcwaliswa.

Amakhanda okugcwalisa asebenzisa ubuchwepheshe be-patent bokuvalwa kwendawo okubushelelezi, akukho ukuthintana namachweba aphakathi kwe-interwall ngakho-ke kungabikho ukungqubuzana kokukhiqiza izinhlayiya; iphinde igweme ukuchichima kwesixazululo okubangelwe ukushintsha kosayizi wezimbobo ukwenza izimbobo zingavalwa ngamakhanda okugcwalisa.

Yamukela isilawuli esithuthukisiwe se-PLC kanye nendlela yokugcina i-valve edidiyelwe, isifunda esilula, ukusabela kokusebenza okusheshayo, ukugijima okuphephile nokuthembekile. Ingxenye yokugcwalisa ihlanganiswe nengxenye yokuvala ibe yiyunithi eyodwa, idinga kuphela uhlelo olulodwa lokulawula ugesi kanye neyunithi eyodwa yokusebenza komshini womuntu; okungenani oyedwa u-opharetha uyancishiswa, agweme ukubi njengokungahambelani phakathi kwama-opharetha amabili, futhi kwenyusa ukuphepha nokuthembeka kwezinto zokusebenza.

Isibonisi sesikrini sokuthinta futhi sisebenzisa sonke isilawuli sezinga lokushisa ngokunembile. Ikakhulukazi kunikeza ukushintshashintsha okuncane kokuqala kanye nezikhathi zokuma, ukubekezelelana kungaba ±1℃.

Iphaneli yokuphrinta ifakwe epuleti le-aluminium ngebhawodi le-S/S stud, gwema ukuxega kwentambo epulatifeni ngemva kokusetshenziswa isikhathi eside.

Umqulu wefilimu ubekwe ngokungezwani okufanayo kusuka ezinhlangothini ezi-4 ukuze kuqinisekiswe ukushuba kwefilimu nokusebenza kahle. Isiqephu sefilimu izinhlangothi kwesokunxele nakwesokudla zilungiswa yipuleti lendawo elilungisekayo, ukuze kuqinisekiswe isivinini sokuphakela nokunemba.

Isiteshi sokushisa kanye nesiteshi sokuvalwa kokushisa samukela uphenyo lwenaliti elayishwe entwasahlobo ukuthola izinga lokushisa lesikhunta, ukufakwa okulula nokuhlakazeka, akulula ukuphuka, ukubekezelelana phakathi kuka-± 0.5 ℃.

Shintsha indlela yokubeka uphawu ukuze uvikele isilinda, gwema ukushisa isikhathi eside kuyo.

Izintambo ezichwepheshile zangaphandle, zihlukanise izintambo ngokulandela izigaba ezihlukene, ukubukeka okuhle nokunakekelwa okufanele.

Lungisa isikhunta esiphansi, kodwa gcina ipuleti lokupholisa, ukuvikela ifilimu lapho umshini ucisha.

Ukuvalwa kokushisa okuzungezile kusebenzisa isikhunta esikhethekile, faka ipuleti lokupholisa lesikhunta esiphezulu esigcwele intwasahlobo.

Faka uhlelo lokuphakelayo oluzenzakalelayo ukuze uxazulule inkinga yokuvinjwa nokuminyana, unciphise umfutho wabasebenzi. Engeza i-ionic yokuhlanza umoya kanye nedivayisi yokuthola ukuze uthuthukise ukucaca komkhiqizo.