Umugqa Wokukhiqiza Izixazululo ze-PP IV

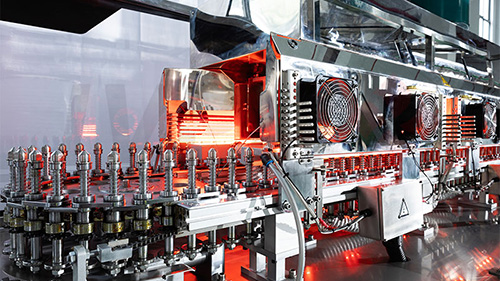

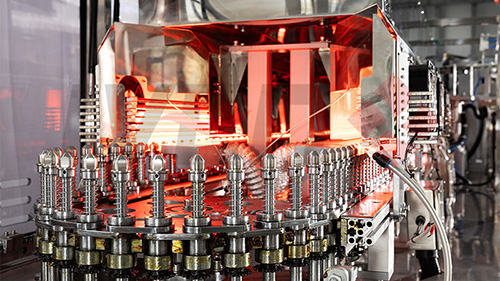

Umugqa Wokukhiqiza I-Othomathikhi we-PP Bottle IV ufaka imishini yokufaka izixazululo ezi-3, umshini wokujova / we-Hanger / Hanger Umugqa wokukhiqiza unesici esizenzakalelayo, esinobuntu futhi esihlakaniphile ngokusebenza okuzinzile nokulungiswa okusheshayo nokulula. Ukusebenza kahle kokukhiqizwa okuphezulu kanye nezindleko zokukhiqiza eziphansi, ngomkhiqizo osezingeni eliphakeme okuyisinqumo esihle kakhulu sebhodlela lePulasi le-IV solution.

Umshini wokujova / we-Hanger / Hanger+ Umshini wokuqhuma ibhodlela+ Umshini wokugcwalisa wokugcwalisa wokufaka uphawu

| Iisihloko | Imodeli yomshini | |||||

| CI-PS4 | CI-PS6 | CI-PS8 | CPS10 | CPS12 | ||

| Umthamo wokukhiqiza | I-500ml | 4000bph | I-6000bph | I-8000bph | 10000bph | I-12000bph |

| Ubude bebhodlela likaMax Bottle | mm | I-240 | I-230 | |||

| Ukuphakama kwe-Max Preform (ngentamo) | mm | I-120 | 95 | |||

| Umoya ocindezelwe (m³ / min) | 8-10Bar | + | + | 4.2 | 4.2 | 4.5 |

| 20gaba | 2,5 | 2,5 | 4.5 | I- | 10-12 | |

| Amanzi Amnyama (M³ / H) | I-10 ° C (ingcindezi: 3.5-4bar) 8hp | 4 | 4 | I-7.87 | I-7.87 | 8-10 |

| Amanzi Okuphola | 25 ° C (ingcindezi: 2.5-3bar) | 6 | 10 | 8 | 8 | 8-10 |

| Ubunzima | T | 7.5 | Uhlamvu lweshumi eliphansi | 13.5 | 14 | " |

| Usayizi womshini (ngokulayisha ngaphambi kokulayisha) | (L × w × w × h) (mm) | I-6500 * 4300 * 3500 | 8892 * 4800 * 3400 | 9450 * 4337 * 3400 | I-10730x4337x3400 | I-12960 × 5477 × 3715 |

| Iisihloko | Imodeli yomshini | ||||

| I-XGF (Q) / 30/24/24 | I-XGF30 / 30/24/24 | I-XGF (Q) / 36/3/36 | I-XGF (Q) / 50/40 / 56 | ||

| Umthamo wokukhiqiza | I-100ml | 7000bph | 7000bph | 9000bph | 14000bph |

| I-500ml | I-6000bph | I-6000bph | 7200bph | I-12000bph | |

| Usayizi webhodlela elisebenzayo | ml | 50/100/250/500/1000 | |||

| Ukusetshenziswa komoya komoya | 0.5-0.7MPA | I-3M3 / Min | I-3M3 / Min | I-3M3 / Min | 4-6M3 / Min |

| Ukusetshenziswa kwe-WFI | 0.2-0.25MPA | 1-1.5m3 / h | |||

| Isisindo somshini | T | 6 | 6.5 | 7 | 9 |

| Usayizi womshini | mm | 4.3 * 2.1 * 2.2 | 5.76 * 2.1 * 2.2 | 4.47 * 1.9 * 2.2 | 6.6 * 3.3 * 2.2 |

| Ukusetshenziswa kwamandla | Motor main | 4 | 4 | 4 | 4 |

| Capping oscillator | 0.5 | 0.5 | 0.5 | 0.5 * 2 | |

| Umoya we-ionic | 0.25 * 6 | 0.25 * 5 | 0.25 * 6 | 0.25 * 9 | |

| Ukuhambisa motor | 0.37 * 2 | 0.37 * 2 | 0.37 * 2 | 0.37 * 3 | |

| Ukushisa ipuleti | 6 * 2 | 6 * 2 | 6 * 2 | 8 * 3 | |

Thumela umyalezo wakho kithi:

Bhala umyalezo wakho lapha bese usithumela kithi